Nancy has experience in collaborating with clients across a range of industries and various government agencies. Working for Smithers for 10+ years, she has helped the company set up several new business units in China, and recently leading our information business in the region developing conferences and working on market research projects. Nancy has led multiple consulting projects, and her early market research on new projects has provided key information and data to support both our clients and our own investment decisions.

Nancy holds a bachelor’s degree of arts in English Major from Nanjing University of Science and Technology, and MBA degree in East China University of Science and Technology.

Martin von Wolfersdorff, trading as "Wolfersdorff Consulting Berlin”, is an expert advisor and business partner of Smithers specialising in sustainable carbon blacks. Martin works with Smithers on carbon black consulting projects, writes Smithers reports and is the founder and business partner of the recovered Carbon Black Conference. Martin's corporate assignments were in carbon black, plastic packaging, plastic masterbatch and titanium dioxide. Martin has a Dipl. Ing. (Univ.) degree in chemical engineering from the FAU Erlangen-Nürnberg in Germany.

Paul Ita runs Notch Consulting, a Massachusetts-based research company dedicated to the market research needs of the global specialty chemicals industry. Mr. Ita focuses on raw materials for the global tire and rubber industries, with a particular focus on carbon black, silica, and rubber chemicals. Through Notch, he publishes the Carbon Black World Data Book and the Carbon Black Quarterly Newsletter.

Ms. Shen Yan is the Vice President of the China Tire Recycling Association and previously served as Chairwoman of Nantong Huili, the largest Reclaimed Rubber company in China. With extensive experience in Reclaimed Rubber and Carbon Black industries, she is committed to driving the sector's sustainable development. Ms. Shen also advises several companies in the field, providing strategic support and guidance. Through her efforts, she successfully advocated for the import of Recycled Tire Powder into China.

She plays an active role in promoting green development and technological innovation, enhancing China’s influence in the global recycling industry.

Joined Continental in 2012 with a focus on supplier development, specializing in rubber raw material production processes, applications, and market intelligence. Possess over 10 years of in-depth experience, particularly in the fillers segment.

From 2021 to 2022, served as Global Manager – Supply Chain Due Diligence at Continental’s headquarters in Hannover, Germany, where I led initiatives in sustainability risk assessment and mitigation across the global supply chain.Well-versed in regulatory compliance, including the German Supply Chain Due Diligence Act (LkSG) and the EU Corporate Sustainability Due Diligence Directive (CSDDD).

Sky Xue holds a bachelor's degree in Polymer Science and Engineering from Zhejiang University and a doctor's in Polymer Science from the University of Akron. He has been with Goodyear Tire & Rubber for 6 years, primarily responsible for sustainable materials development in the Asia-Pacific region and leading the 100% sustainable material tire project.

Jeff Shiue has been serving as Eco Infinic's General Manager since 2024. He was a chemical engineer and joined Eco Infinic’s parent company Sheico Group after receiving an MBA from NYU in 2010. He was Sheico’s Director of Sales and R&D for 8 years and spearheaded efforts to make wetsuits more eco-friendly. As Sheico invested more resources to enable Eco Infinic to expand, Jeff transitioned full time to the subsidiary to guide its growth.

Pieter ter Haar is one of the founding members and current Chair of ASTM committee D36 on Recovered Carbon Black (rCB). He is Director rCB for Circtec, and an expert in recovered carbon black (rCB), pyrolysis, and a former rubber compounder. He holds a Chemistry degree and has over 14 years of experience in using and producing rCB.

Circtec, headquartered in the United Kingdom is a leading ELT pyrolysis company. Circtec has invested over €230 Million over the last 15 years and has activities in 5 European countries, including ELT collection. Upon its full completion, Circtec’s flagship facility in the Northern Netherlands can process 5% of all European ELT and produce rCB, Marine biofuel and Circular Naphtha.

Pieter is also part of the Advisory committee of the Smithers Recovered Carbon Black World conferences in Europe.

With over 13 years of experience in supporting and managing of technical complex projects and in international sales at HOSOKAWA ALPINE (Germany), Christian combines in-depth engineering knowledge with a customer focus. In his role as a project and sales engineer, he is responsible for the successful design, planning, and implementation of projects, including those for rCB plants.

His interdisciplinary expertise makes him a valued contact at the interface between technical engineering, sales, and customers.

At the conference, Christian will speak about practical solutions for rCB grinding and HOSOKAWA's complete Back-End capabilities.

Co-founder waste Tyre recycling businesses at Green Rubber Energy more than 10 years ago 1. Develop a strategic plan to advance the company's mission and objectives and to promote revenue, profitability, and growth as an organization. 2. Oversee company operations to insure production efficiency, quality, service 3. Identify acquisition and merger opportunities and direct implementation activities. 4. Evaluate performance of executives for compliance with established policies and objectives of the company and contributions in attaining objectives. 5. Promote the company to local, regional, national, and international constituencies.

Jackie Chen is the Deputy Section Manager of the R&D Department at Enrestec, where he has been driving advancements in sustainable materials and recovered carbon black applications for the past four years. He holds a Master’s degree in Civil and Environmental Engineering from National University of Kaohsiung, Taiwan, specializing in material sustainability. His research on silicon carbide synthesis utilizing eco-friendly carbon sources and recovered silica underscores his dedication to circular economy solutions. With expertise in rubber processing, tire pyrolysis technology, and carbon black optimization, Jackie remains focused on developing innovative approaches to enhance material performance and expand industry applications.

Hu Yunchao, R&D engineer from Doright, mainly focuses on the pelletizing and drying systems for carbon black and rCB.

He is in charge of the company's pelletizing laboratory and has extensive experience in rCB pelletizing and drying.

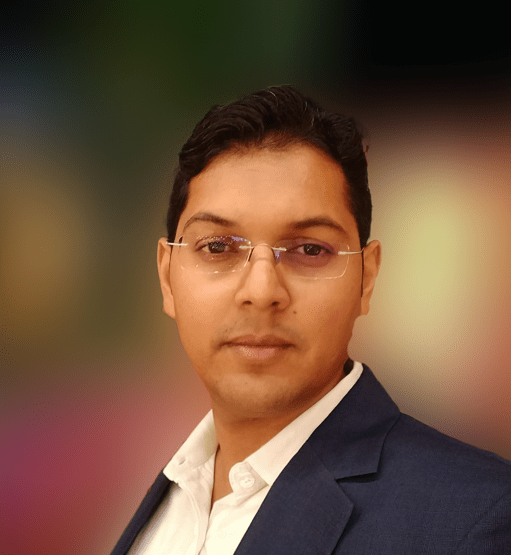

Sagar is the Assistant General Manager of Strategy Development and Execution in Epsilon Carbon Private Ltd. He holds a B.Tech in Chemical Engineering and has specialised in Advanced Strategic Management from the prestigious Indian Institute of Management Kozhikode. Sagar has over 15 years of experience in Strategy development across various sectors such as Automobile, Electrical & Hydraulics, HVAC & Refrigeration and now the Chemicals sectors.He has enabled strategic decisions in new market entry, capacity additions, product portfolio expansion and corporate strategy planning.Since 2022, Sagar has been focusing on strategy development and implementation for the Carbon Black business of Epsilon Carbon and is driving multiple strategic initiatives in the business.

Biswajit Paul is a highly experienced, a well-known professional and technocrat with over 33 years of experience in the carbon black and tire industries across India, Europe, the Middle East, and Africa (EMEA).

Key Roles and Experience

Current Role: Technical Director at Shine Carbon and Chemicals Private Limited (part of the Ralson-Shine Group), a position he has held since 2023.

Expertise and Contributions

• Specialization: He is an expert in product technology & business developer, developing customized carbon black grades for tire and non-tire applications and presented research papers at international conferences like CBW 2024 in Europe and CBW 2025 in U.S.A.

Education: He holds a Master of Technology (M.Tech) in Plastics & Rubber Technology from the University of Calcutta and is a Six Sigma Black Belt holder.

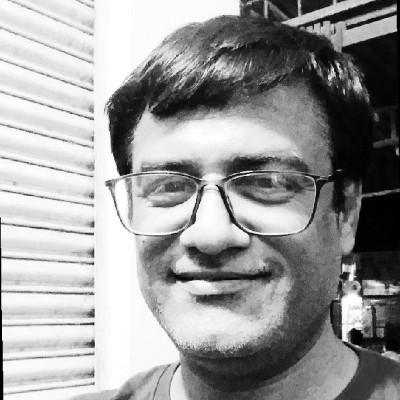

Franklin Raj is a Pyrolysis Business Analyst at Robert Weibold GmbH, specializing in tire pyrolysis and recovered carbon black. He supports a wide range of stakeholders — from project initiators to OEM manufacturers — across APAC and Europe with technical assessments, strategy, and market research. Over the past years, he has contributed to major industry projects and shared his expertise at conferences, helping stakeholders advance the transition towards a sustainable and circular business-economy.

Ravi Rathi, a first-generation entrepreneur and Chartered Accountant, is the Director of Rathi Group, based in the port city of Chennai, India. He initiated the company's journey into sustainable innovation by setting up the first pyrolysis unit in 2012. Rathi Group now covers the full spectrum of tyre recycling, from shredding to pyrolysis to producing recovered carbon black, ensuring complete quality control and consistent product .

Their Recovered Carbon Black, marketed under the brand CAPITAL CARBON, is ISCC Plus and ISO 9001 certified. It is used by major tyre and MRG brands in India and is exported worldwide. Ravi Rathi’s leadership continues to drive Rathi Group's growth in sustainable tyre recycling.

Flora serves as Director and Deputy General Manager of Qingdao Ecostar Resource Recycling Equipment Co., Ltd. With nearly ten years of deep involvement in the environmental protection equipment sector, she has long been dedicated to the research, development, and promotion of waste tire recycling technologies and equipment. She possesses extensive practical experience in the market development of pyrolysis equipment, project implementation, and industrial chain resource integration.

Leading her team, she has consistently expanded the company's market presence domestically and internationally, successfully exporting the self-developed, intelligent, and modular waste tire pyrolysis equipment to multiple countries and regions. Her efforts earned wide recognition and a strong reputation, establishing her as a key figure in advancing the development of the green industry.

Bio coming soon...

Prof. Huang Qunxing specializes in theoretical and technological research on stepwise pyrolysis and high-value utilization of solid wastes. He serves as the President of the Global WtERT Council and the Senior Expert in China’s National Key R&D Program. He has served as the principal investigator for over 30 research initiatives, including the National Key R&D Program, the National Natural Science Foundation of China (NSFC), and multiple industry-supported projects. He got many honors including the Team Award and the Second Prize Award of the National Science and Technology Progress. He has developed a new pyrolysis technology and built two commercial rCB recovery plants. One of the plants has been awarded the Top 10 Successful Demonstration Plants for Carbon Reduction.

Currently serves as the production director and chief process engineer of ECOWELL. Has been dedicated to the field of waste tire resource comprehensive utilization for 6 years. Led the research, design, and construction of the continuous thermal cracking project, the recycled carbon black deep processing project, and the wheel scrap cracking oil refining project at the ECOWELL factory; holds multiple technical patents in this industry.

.png?ext=.png)

Suhas Dixit is an entrepreneur and seasoned professional with over 15 years of experience in the field of advanced recycling and biofuels. As a chemist and inventor with 12 patents in pyrolysis and pyrolysis oil purification, Suhas is committed to developing technologies that transform plastic and biomass waste into high-quality liquids. As the founder and CEO of APChemi, Suhas has led the company in delivering 47 successful projects in plastic pyrolysis and oil purification. His innovative solutions have gained global recognition as a driving force in plastic circularity and decarbonisation. He is a sought-after keynote speaker at international forums on Plastic/Biomass Pyrolysis, Chemicals/ Advanced Recycling, Plastic Waste Management and Sustainability. With a strong commitment to driving positive change, Suhas is dedicated to delivering innovative and sustainable solutions that address critical global challenges, such as plastic and biomass waste management, circular economy, and decarbonization. His extensive knowledge and experience in developing and implementing cutting-edge technologies have led to numerous successful projects and patents in the field of advanced recycling and biofuels.

Young entrepreneur, deeply passionate about research and dedicated to advancing environmental sustainability. With a keen interest in carbon markets, water and waste management, decarbonization, climate change mitigation, achieving net zero emissions, promoting the circular economy, and nature-based solutions. Exhibits strong research, project management, and analytical abilities, thrive in multicultural environments, excelling in teamwork, communication, leadership, critical thinking, and problem-solving. I consistently deliver high-quality results while managing multiple assignments under tight deadlines, driving innovative solutions for and sustainable development.